Why Plastic Pallets?

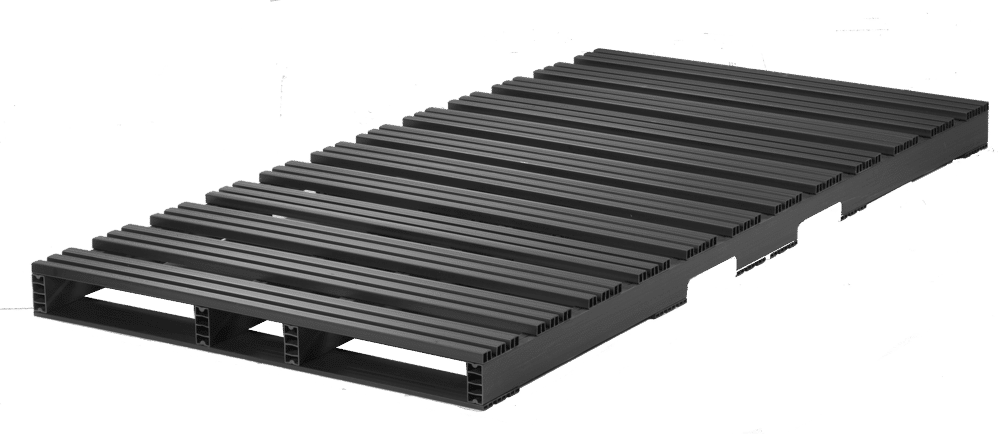

Plastic pallets have become a smart, long-term alternative to traditional wood pallets across a wide range of industries. While wood has been the standard for decades, plastic pallets are rapidly gaining momentum—and for good reason.

Although the upfront cost of a plastic pallet may be higher, the long-term return on investment is hard to beat. With their superior durability, consistency, and resistance to damage, heavy duty plastic pallets offer reliability that wood simply can’t match.

Whether you’re transporting goods across the country or storing inventory in a warehouse, plastic pallets deliver consistent performance, lower maintenance costs, and longer service life.

Industries That Use Plastic Pallets

Plastic pallets and plastic skids are used in nearly every major industry due to their strength, cleanliness, and long-term value. While the list is extensive, here are a few sectors that frequently rely on custom pallets and plastic solutions over traditional wood:

- Food and beverage processing

- Pharmaceutical and medical supply distribution

- Retail and e-commerce

- Manufacturing and assembly

- Warehousing and logistics

- Export and international shipping

From cleanroom operations to rugged manufacturing floors, plastic pallets provide a reliable, reusable base for moving products safely and efficiently.

Safety Benefits of Plastic Pallets

Workplace safety should always come first. Traditional wood pallets often pose risks: splinters, broken boards, exposed nails, and inconsistent construction can lead to injuries and product damage.

In contrast, plastic pallets and plastic skids are manufactured with smooth edges and uniform dimensions. They don’t harbor nails or splinters, and they’re less likely to break under stress. This makes them a safer, more consistent choice in both automated and manual handling environments.

Additionally, plastic pallets are non-porous and easy to sanitize. They can be high-pressure washed, reducing the risk of bacterial contamination—especially critical in food-grade and pharmaceutical industries.

Export and Shipping Compliance

Exporting products across international borders involves meeting strict regulations—especially when using wooden shipping materials.

Plastic pallets are exempt from ISPM-15 regulations, which means they don’t require fumigation or heat treatment for international shipping. Their compliance, combined with their durability and resistance to mold and pests, makes plastic pallets the preferred choice for global logistics and freight-forwarding companies.

Plastic pallets are exempt from ISPM-15 regulations, which means they don’t require fumigation or heat treatment for international shipping. Their compliance, combined with their durability and resistance to mold and pests, makes plastic pallets the preferred choice for global logistics and freight-forwarding companies.

Whether you’re shipping across the state or overseas, plastic pallets simplify compliance and reduce delays.

Performance in Wet or Harsh Conditions

Anyone who has used wood pallets knows the issues water can cause: swelling, warping, mold, and rot. Over time, exposure to moisture leads to structural failure, safety risks, and rising replacement costs.

Plastic pallets are water-resistant and built to perform in wet, humid, or cold environments. They don’t absorb moisture and won’t break down when exposed to water—making them ideal for wash-down environments, refrigerated storage, and outdoor use. Heavy duty plastic pallets also maintain their shape and strength even after repeated cleaning cycles.

Plastic pallets are water-resistant and built to perform in wet, humid, or cold environments. They don’t absorb moisture and won’t break down when exposed to water—making them ideal for wash-down environments, refrigerated storage, and outdoor use. Heavy duty plastic pallets also maintain their shape and strength even after repeated cleaning cycles.

For any operation where hygiene, weather resistance, or durability matters, plastic pallets are the clear winner.

Why Choose Custom Built Plastic Pallets?

At Custom Built Plastic Pallets, we design and manufacture custom pallets and plastic skids that meet your exact specifications. Whether you need a lightweight option for internal use or a heavy duty plastic pallet for demanding supply chain applications, we can build a pallet that fits your operation.

Explore our full line of plastic pallet options or contact us to build a custom pallet tailored to your specific needs.